Looking for Brick Slips for facade systems?

Visit our dedicated website.Looking for Brick Slips for facade systems?

Visit our dedicated website.

You need to source imperial size bricks for your building project, but where do you start?

If you don’t know anything about brick sizes and it’s your first time looking for imperial bricks, or if you do know a thing or two but need information to help you find the bricks you need, you’ll find it here.

This guide reviews the characteristics and history of imperial sized bricks to give you a solid understanding of them, and provides practical advice on how to source and use them for your next project.

So where to begin?

Bricks have been a defining feature of British architecture for centuries.

From Tudor cottages to Victorian terraced houses and even historic castles, brickwork is still as popular today as it was back then.

Since the widespread implication of metric sizing in the early 1970s, most modern clay brick production for the UK has shifted to metric size bricks.

The problem is, if your property was built before then, it’s likely that the bricks used for the façades are an imperial size. This can be challenging to match if you’ve never used them before, especially for renovations and repair work.

First, it’s important to understand the difference between what is meant by metric and imperial sizes.

Prior to 1965, the sizing of bricks in the UK was measured in inches, or imperial size.

After the introduction of the metrication programme in 1965, the construction industry needed to adapt to a new standardised size. Following much consideration and building trials, a new metric size for bricks was introduced, which was advised in BS 3921 in January 1970.

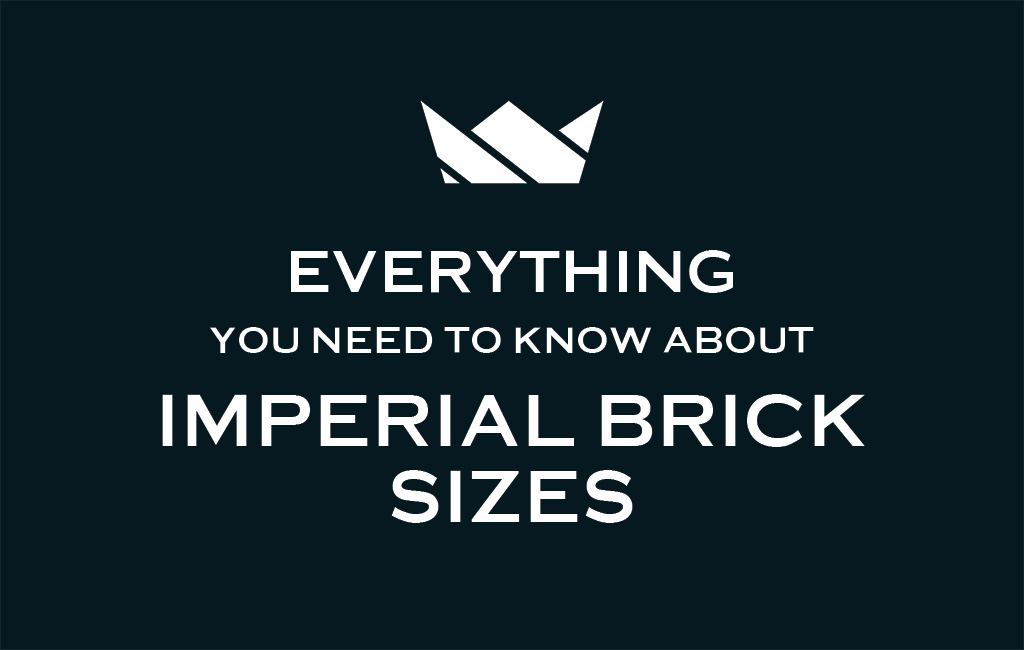

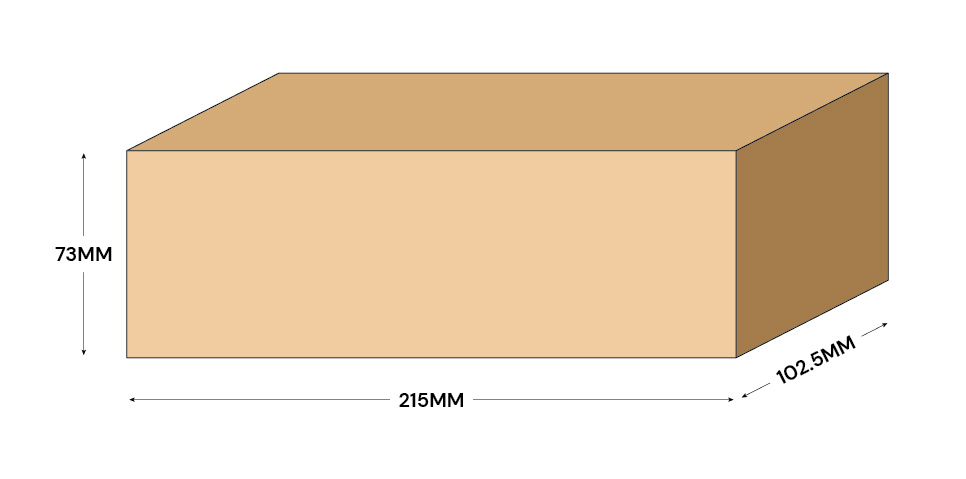

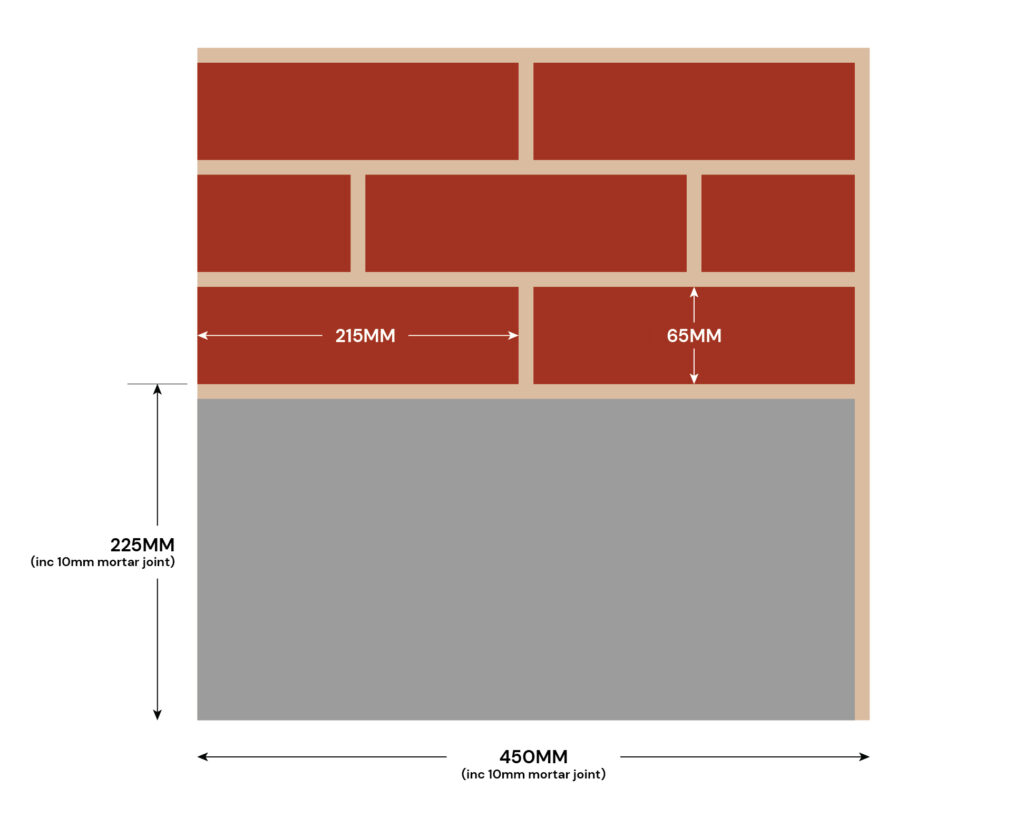

The new standardised metric size brick was defined as 215 x 102.5 x 65 millimetres (mm), allowing for a 10mm mortar joint.

The decision on the final size consisted of several factors. One of the most important considerations was the ease of handling in relation to the speed of bricklaying, or in other words, ensuring the brick wasn’t too large to be held in one hand.

Another significant consideration was how the proposed sizing fit within a 100mm module size. A module size is a recommended manufacture size that all building components should be designed within, either singularly or in multiples of 100mm.

The benefits of adhering to this universal module size include reduced scrap material generated from products needing to be cut on-site, reducing the need for bespoke production and being able to streamline the range of product sizes held in stock.

Though the new metric size didn’t adhere to the 100mm module, it did fit within a 300mm module multiple (a preference described in BS 4011). The benefits of this ensured the new size not only aligned with metric blockwork but allowed the new size bricks to be used in conjunction with imperial size bricks.

Imperial brick sizes are generally larger than the standard modern metric size of 215 x 102.5 x 65mm and are measured in inches.

There is no definitive imperial brick size, only popular sizes used throughout the course of previous centuries.

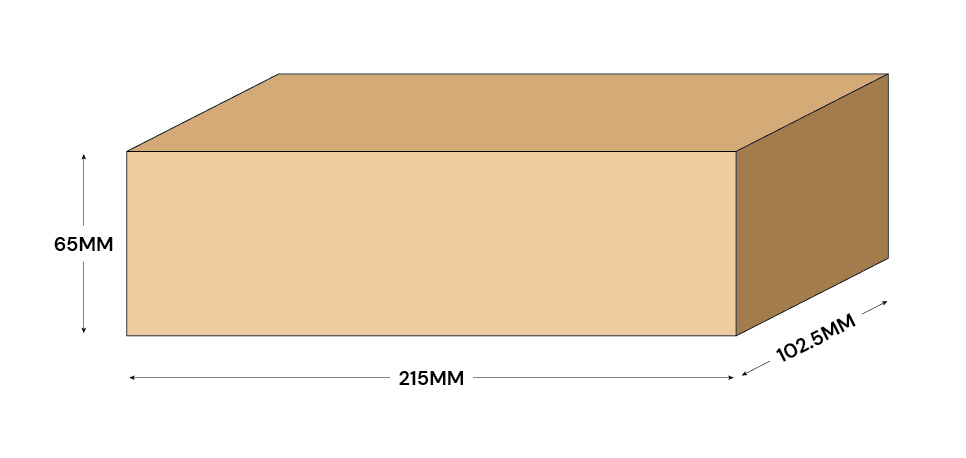

Imperial bricks are popularly known to measure 228mm in length and 108mm in width, while their height varies between 50mm, 68mm, 73mm, 75mm or 80mm, depending on their place of origin and the period they were manufactured in.

Before the introduction of the metric sizing system, brick sizes were mostly determined by specifications from the era they were produced in, and regional location. Sizing wasn’t always consistent, and you’d be hard pressed to source the exact size you needed, in the right colour and texture, at the right price.

Throughout history, imperial brick sizes have adapted and evolved in response to advances in manufacturing and industrial capabilities, reflecting the progress of each era.

Knowing which period your brickwork originates from can help you to source the size you need.

The use of bricks in Britain dates back to the Roman period, with the first documented use dating to AD 43.

Roman brickmaking was a well-developed craft, with bricks used extensively in their buildings. One of the earliest surviving examples today is the iconic Bathhouse complex in Bath.

Similarly to how traditional handmade bricks are produced now, raw clay was dug and mixed with organic materials and shaped using wooden moulds. The resulting bricks were left to dry in the sun for several days before being placed into a kiln to fire.

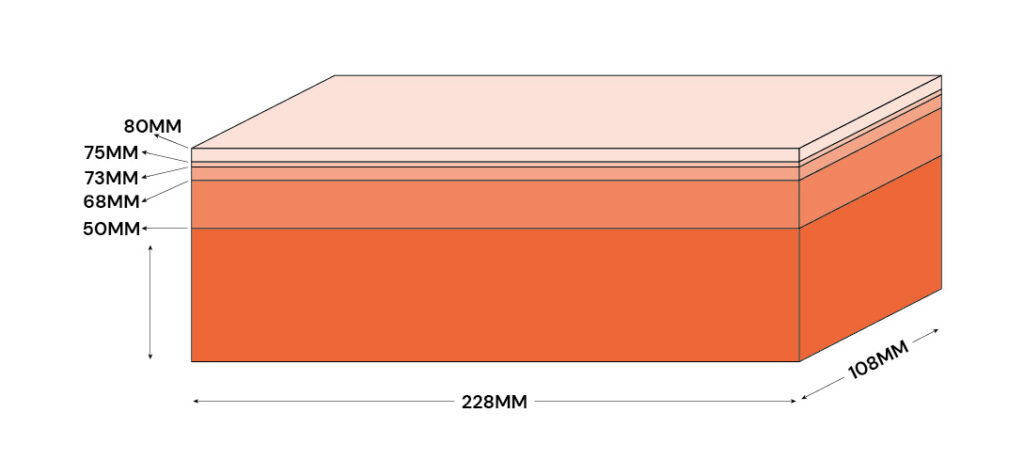

The bricks bore little resemblance to the sizes we are accustomed to today.

Though dependent on the intended application, they were generally found to be between 300-500mm in length, by 100mm in width and 40mm in height. These would be similar in appearance to the long format (or linear) bricks produced today.

After the fall of the Roman Empire in the 5th century, the medieval period saw brickmaking become obsolete, except for some small-scale, localised production for chimneys and hearths.

The Tudors significantly reinstated the art of brickmaking.

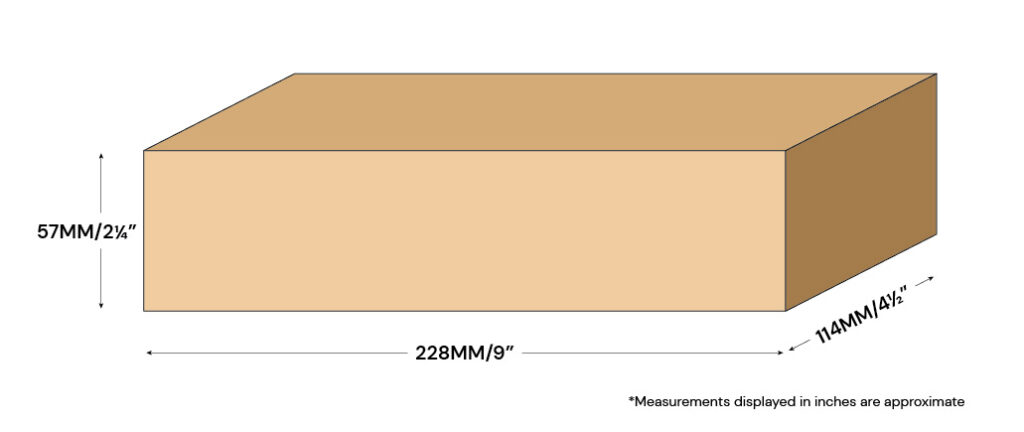

Between 1485 and 1603, bricks were used in abundance to showcase wealth and fortune. A charter introduced in 1571 stipulated the dimensions of bricks to be 9 x 4½ x 2¼ inches in size, which is where the 2-2¼ inch (50-57mm) brick height measurement originates from.

Fast forward to the Georgians, the 1700s saw a big improvement in brick manufacture.

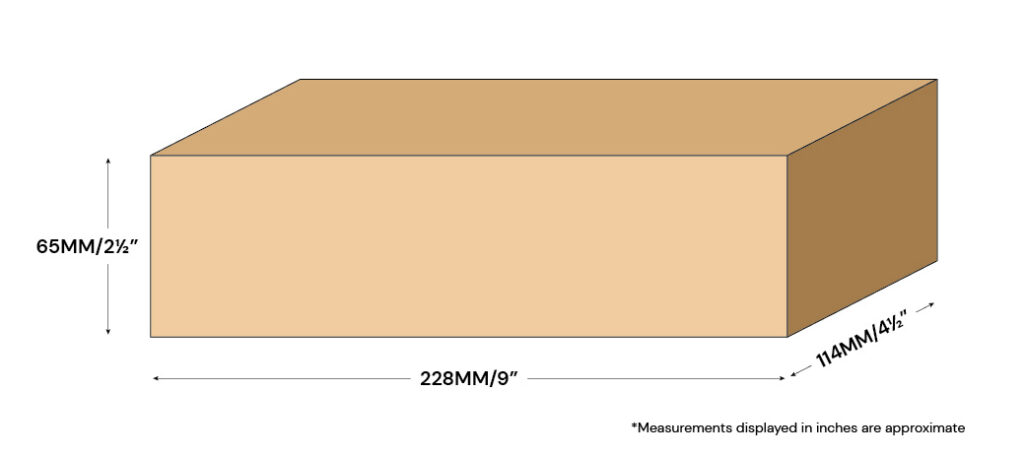

Improved methods of production meant sizing was more consistent. A general size of 2½ inches (65mm) in height was adopted, however in 1784 a tax on bricks was enforced to fund the war efforts, resulting in manufacturers considerably increasing their sizes to compensate.

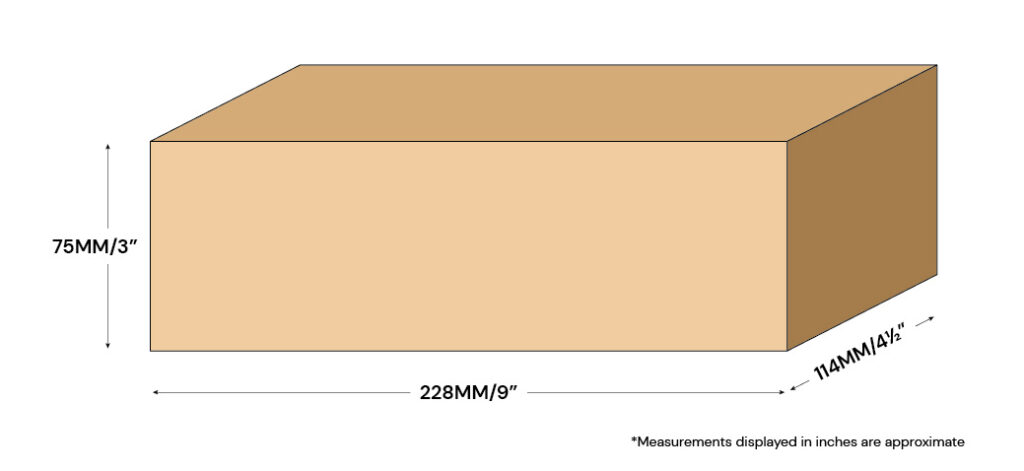

This was capped by the treasury who imposed a size limit of 3 inches in height, by 10 inches in length and 5 inches in depth. Anything more than this was charged double duties. As a result, the 3 inch (75mm) height size became popular during this time.

Moving to the Victorian era, the Industrial Revolution brought a substantial increase in brickmaking efforts.

Manufacturers began to mechanise their production and newly established railway links meant bricks were no longer restricted to the availability of local supply and were distributed countrywide.

Sizes were typically 9 inches in length by 4¼ inches in width, and the height varied between 2-3 inches (50-75mm).

Bringing us to the 1900s, the ‘British Imperial Standard for Common Bricks Made of Clay’ was introduced in 1903 to provide a uniform standard for brick manufacturing in the UK.

According to the standard, clay bricks were required to be produced in a size of 9 inches long by 4½ inches wide, with a height of 3 inches (equivalent to 228 x 114 x 75mm).

This was the last significant size advisory and remained in use throughout the 20th century until the introduction of metric sized bricks.

If you don’t already know your brick size, measure 10 of your existing bricks and take the average size. This can help you establish which period your brickwork originates from, which helps with sourcing. Many manufacturers and retailers name their bricks in accordance with their age, suitability to an era, or even advise which type of properties they are likely to be suitable for.

When sourcing imperial size bricks, you have two choices – select new bricks that are closest to or match the size you need, or buy reclaimed bricks.

There are pros and cons to both, so we’ll take a look at each option.

Many modern brick manufacturers produce clay bricks in traditional imperial sizes.

If you’re extending or renovating a period property, chances are that your original brickwork won’t match the modern metric brick size. For this reason, there are several imperial sizes available from various manufacturers.

The most common imperial size bricks produced today are 228 x 108 x 68mm and 228 x 108 x 73mm.

Some manufacturers also produce what is known as ‘hybrid’ size bricks.

These are an imperial size height (i.e. 50/57/68/73/75mm) with a metric length and width (215 x 102.5mm).

Hybrid size bricks have gained popularity in recent years due their benefit of being easier to match up with modern size concrete blocks.

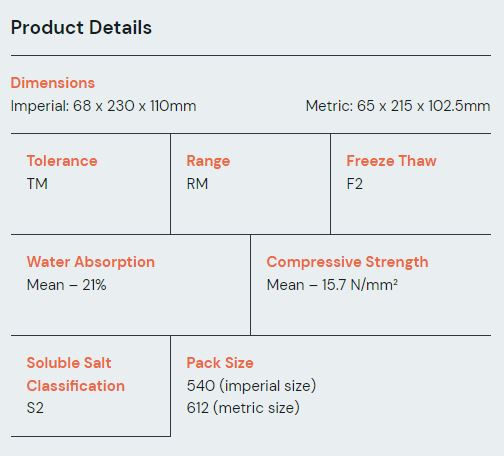

Another benefit to using new bricks is the provision of performance data and test results.

To be suitable for use in the UK construction market, clay bricks must be tested for size, compressive strength, water absorption, frost resistance, and soluble salt content against the methods and classifications specified under the British Standard BS EN 771-1.

Though you should be able to source the correct brick size for your property, there can be some restrictions in availability of colours and textures. You may also find some limitations when needing to match standard stock lines to your aged and weathered brickwork, however some manufacturers may offer bespoke brick matching services.

If you’re looking for an exact match to original brickwork, reclaimed bricks are a viable option.

Reclaims are obtained from building demolitions where the bricks from a dismantled building are sorted, cleaned, packed and resold for use in new building projects. Due to their previous building lifecycle, they’re often already aged and weathered by the British climate.

Some manufacturers and builders merchants may stock reclaimed bricks, though your best bet is to visit reclamation yards and look through their stock. Speak to their staff and be sure to have a clear image of what you’re matching to, or better still, take along a brick sample from the original walls if possible.

Unfortunately, one of the biggest disadvantages of sourcing reclaimed bricks is that they’re often in short supply.

Continual stock is rare unless you’re lucky enough to come across a supply from a large, continual demolition project and even then, the demand and competition from other buyers can be high.

Additionally, reclaimed bricks are not supplied with any test data. Their only assurances come from being exposed to the British weather for an unspecified length of time before demolition.

It should also be noted that damage to bricks can occur during the demolition process, but these should be sorted and discarded before packing.

Unless the intention is to use reclaimed bricks for the construction of a new build property, there’s often a compromise in sourcing. You may find the perfect colour and finish to match existing brickwork, but the size may not match or vice versa.

Sourcing reclaims depends heavily on the availability of stock, but if you can find a good match they can blend seamlessly with your original brickwork.

If you’re not sure which option would be best for your project, our detailed guide on choosing between reclaimed and new old-style bricks may help you decide.

Depending on the age and style of your property, you may find that you cannot obtain the perfect size brick for your extension or renovation work.

From here you have two choices.

If the build requires a substantial quantity of bricks (usually 20k+) you can enquire with manufacturers about the possibility of having bricks made to order for you, though be aware that this option can have long lead times.

However, if you don’t require that many bricks, you may need to compromise.

Though brick size is important, this can sometimes be compromised. If you find the perfect visual match to your original bricks but the size slightly deviates from the required size, it may not be noticeable, especially when using handmade bricks.

Something to be aware of is size tolerance – all bricks have a tolerance in size. This means that the actual size of a single brick can differ by a few millimetres from the stated production size. You can find out what these tolerances are by noting the brick ‘tolerance’ and ‘range’ classifications advertised by the manufacturer and checking them against tolerance categories.

Most manufacturers will advertise the tolerance and range on their website product page, or on a Declaration of Performance document.

Below is a screenshot of product details from one of Imperial’s online products.

From this, you’ll be able to work out whether the bricks are suitable for your project. Although tolerances may seem like a big issue, they aren’t. Bricklayers are used to working with size tolerances, so a few millimetres difference shouldn’t cause a problem, but if you’re concerned talk things through with your builder.

When choosing a size that deviates from your stated size, always select the closest match in height over any other dimension. Bricks are most often 50, 65, 68, 73 or 75mm in height, and sometimes even as large as 80mm.

If the height is a close match, it should blend with existing brick courses (rows) and a few millimetres tolerance can be accounted for within the mortar joint, which is usually 10mm wide.

If the length of the bricks is wider or shorter than those you need to match, it’s down to your preference on whether you want to use them.

[Example of misaligned brick sizes used to build an extension]

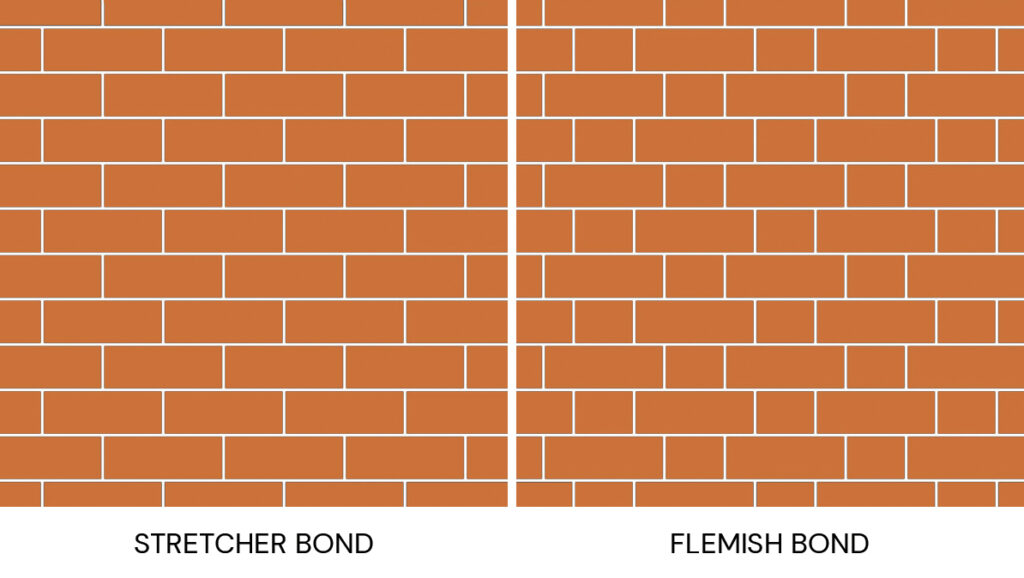

Regarding the width of the brick, if you’re using a stretcher bond, this is the measurement you simply won’t see once the bricks are laid so is nothing to worry about aesthetically. Though if you’re extending or infilling using a different brick bond, such as an English or Flemish bond, the return (end) face of the bricks will be seen so the measurement needs to be considered.

Generally, if the bricks you source are only a few millimetres different from the originals you’re matching to, don’t worry too much.

If you’ve found the exact size you need, in the right type of brick, but the colour or finish doesn’t quite match your brickwork, you still have options.

Excluding engineering quality bricks, clay bricks can be tinted to change their facing colour and/or weathered and aged to make them look older.

Some manufacturers offer this as a service, or your contractor may have experience in doing it. The best way to find out is to speak to them.

On any account, it is highly recommended to build a sample panel wall to ensure the suitability of the bricks you’ve sourced against any original brickwork before commencing the full build.

Whether you’re building an extension or a brand-new property, you’ll most likely be using metric size blocks.

Metric size bricks are intentionally designed to be compatible with modern size blocks. The dimensions of blocks, plus their mortar joints, match up with the dimensions of clay bricks and their mortar joints.

The metric block size designed to be used with metric bricks is 440mm in length by 215mm in height.

Length

One 440mm block + 10mm joint = 450mm

Two 215mm bricks + two 10mm joints = 450mm

Height

One 215mm block + 10mm joint = 225mm

Three 65mm bricks + three 10mm joints = 225mm

When using imperial size bricks for your project, there will be a difference in the ascending height of blockwork to brickwork joints. Though there’s no need to worry – the use of adjustable wall ties or Fastrack channel ties will account for the height difference.

Adjustable wall ties can be bent/sloped down slightly from the blockwork joint to the brickwork joint, whereas Fastrack Channels are built into blockwork and compatible ties are installed at the corresponding brickwork joint.

Additionally, coursing blocks may also be used to further align the joint heights.

If you have any concerns about the suitability of the imperial bricks you’ve sourced, always speak to your builder who will be able to advise accordingly.

Imperial size bricks are a lot more common than you may first realise. If you think about all the buildings in the UK today which were built before 1965-1970 – there’s a lot!

Though it may seem a daunting task to find the bricks you need, manufacturers and suppliers are very much aware of the demand for extending and renovating period properties, so always ask for their advice or speak to your builder who is likely to have a lot of experience working with them.

If you have any questions about sourcing the correct brick size for your upcoming project, feel free to get in touch.